Whilst this subject is vast, this essential guide focuses on the key areas of energy management, helping to educate on common issues and provide clarity on the solutions needed to save time, energy and carbon footprint.

What does energy management really mean?

The general consensus for energy management is simply turning things off and cutting your consumption, so why bother with an energy management system in the first place?

Cutting production or service levels means sacrifice, not efficiency.

The main objective of energy efficiency in industry is to continuously reduce energy consumption and associated costs whilst maintaining the same level of service or production.

Energy efficiency = (services + goods + energy produced) / energy consumed

Energy management is not only about getting a cheaper rate and how much you can save with an energy supplier; it’s about how much energy you consume, when you consume it and where it’s being wasted. Understanding this and making small adjustments to your processes will have a huge impact on expenditure, ultimately leading to a more competitive business and better profitability.

Did you know?

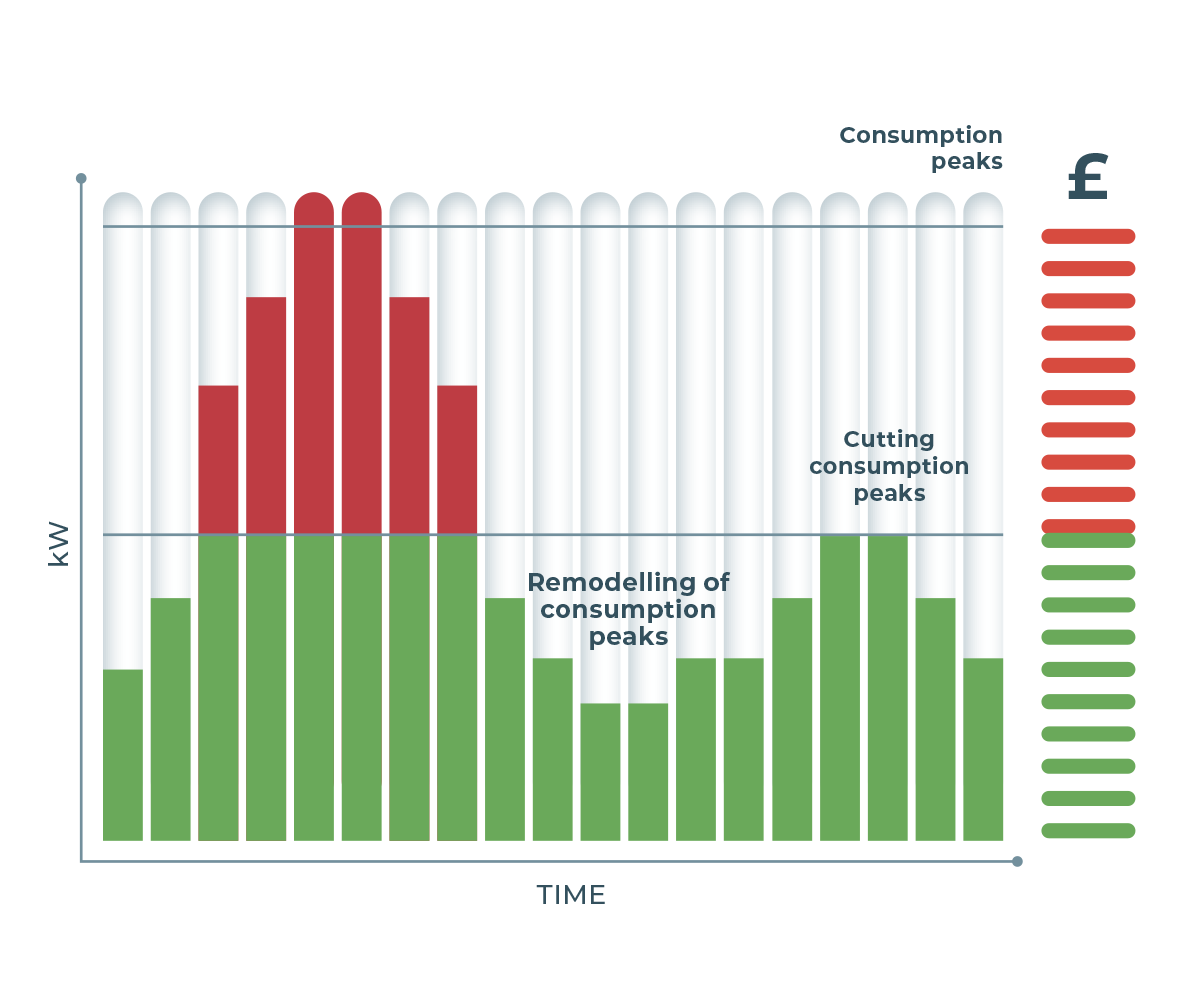

There is a consumption peak on your energy usage, which you may not be aware of, once this limit is reached, you pay a penalty and automatically go on a much higher tariff. Without even realising it, your production costs suddenly rocket, and you start losing profitability.

What are the key areas that waste the most?

Electric motors

Machinery wear and tear

Peak production times

Solar power panels underutilised

Workforce behaviour

Understanding why, and how to offset waste

First, we need to understand what all the key energy cost areas are and where efficiencies can be made.

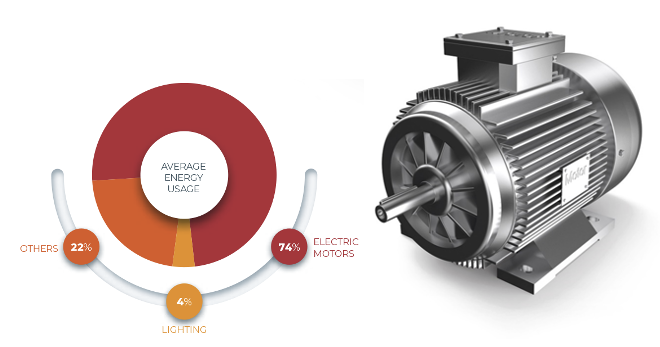

Electric motors

In industry, electric motors are the largest consumer of energy. Efficient motors and inverters help reduce energy usage, but this needs to be quantified in order to optimise the performance of the process.

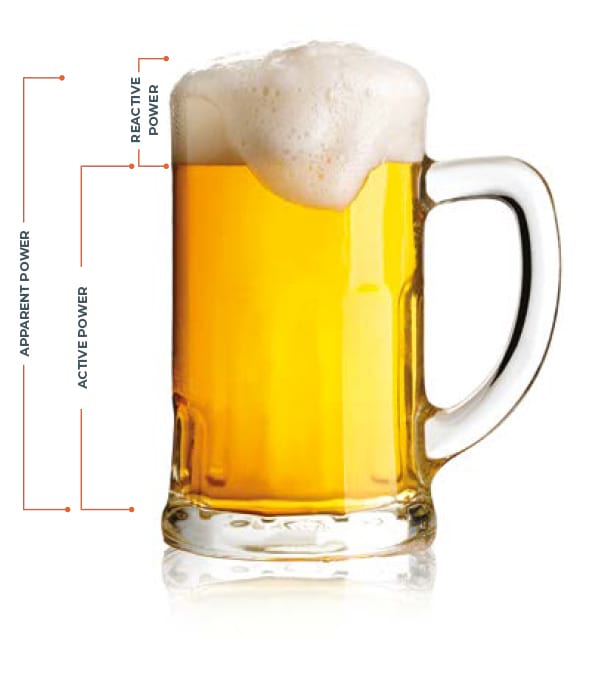

Reduce reactive power?

All motors require two kinds of power to operate: Active Power

(kW (kilowatts)), which is the power to produce the motive force, and Reactive Power (kVAr (kilo-volt-amperes reactive)), which energises the magnetic field.

To work out the efficiency of a motor and how much you are actually paying for, you combine the two values to give you the Apparent Power (kVA (kilo-volt-amperes)).

Would you be happy to pay for the full Apparent Power, knowing you are only using the Active Power element?

To correct the Reactive Power used, capacitors can be locally connected. These capacitors help to balance the Reactive Power to meet the demand of the inductive loads. This will keep that Reactive Power from having to flow all the way from the utility generator to the load, saving energy and money on every electric motor. Using an effective monitoring system can identify which areas require preventative solutions.

Machinery wear and tear

Why does machinery wear and tear use more energy?

Machinery wear and tear result in increased energy usage due to several key factors:

Increased friction: Worn-out components develop rough surfaces, leading to higher friction between moving parts. This friction requires more energy to overcome, increasing overall energy consumption.

Loss of lubrication efficiency: Degraded or contaminated lubricants fail to reduce friction effectively. Inefficient lubrication means more resistance and energy needed for smooth operation.

Component degradation: Worn parts such as gears and bearings do not function efficiently. This inefficiency means the machinery has to work harder, consuming more energy to maintain the same performance level.

Heat generation: Increased friction generates extra heat, wasting energy. Additionally, cooling systems must work harder to maintain safe temperatures, using even more energy.

Vibration and noise: Wear and tear cause imbalances and misalignments, leading to more vibrations and noise. These vibrations create additional resistance, requiring more energy to operate the machinery.

Identifying wear and tear is essential in proactive maintenance to optimise energy efficiency and extend equipment lifespan. An energy monitoring system can highlight where efficiencies are degrading early, so maintenance, repair or replacement can be planned in advance to reduce costly downtime.

Peak production times

Businesses that exceed their agreed peak energy usage or maximum demand levels may face several consequences:

Excess capacity charges:

Applied for using more than the agreed maximum demand.

Excess capacity charges:

Applied for using more than the agreed maximum demand.

Penalty charges:

Imposed by some suppliers to encourage better energy management.

Higher tariffs for exceeding peak usage: Businesses

may be subject to higher tariffs if they exceed peak usage limits.

Managing peak energy usage

Knowing your limits and having the ability to monitor usage can help plan load shifts to avoid penalties and higher tariffs, making each production run as efficient and profitable as possible. Another important benefit from understanding and monitoring energy usage is more accurate job costing and competitiveness.

Solar power panels underutilised

Utilising solar power to reduce energy bills and reducing carbon footprint has great appeal for many businesses. Solar generated energy is classed as green energy, so it counts towards Net Zero targets and once the investment is paid off, it’s free energy… or is it?

Whilst there is a big initial cost, once installed (and depending on energy usage), a business may see a Return On Investment in around 15 years. However, most will not see anywhere near that ROI because most of the energy generated ends up back in the National Grid for a tiny buy back cost.

Why can’t you use all of the energy used from solar?

Essentially, the energy produced is on demand, so whilst the sun is bright and production is running, the business is benefiting from some renewable energy. Usually, the demand for energy is higher than the production and any energy generated before or after this period cannot be stored, and so is put back into the National Grid for minimal return.

So, what’s the answer?

If you have the ability to monitor solar panel energy peaks, you can then plan production shifts to take advantage of more cost-effective energy. This not only improves production profitability, but also reduces the ROI on the initial investment.

Workforce behaviour

This is the quickest fix of all: a simple cultural change in the workplace, so everyone in the business switches off power anywhere it’s not being used, and the business automatically saves £1000s every year.

If you already have an energy management system in place, it should be able to prove these savings in real time. Sharing these results with the workforce can reinforce the importance of these small changes, provide better job security and a healthier cash flow to re-invest into the business for a better future for everyone.

Benefits of integrating ISO 50001 with sustainability reporting-main heading

In the realm of sustainability reporting, integrating ISO 50001, the international standard for energy management systems, can significantly enhance the effectiveness and credibility of sustainability initiatives within an organisation.

ISO 50001 provides a structured framework for establishing, implementing, maintaining, and improving energy management practices, leading to a range of benefits that complement and strengthen sustainability reporting efforts.

Read more on ISO 50001 in our sustainability post.

Compulsory energy reports

If your business uses 40,000kWh or more, you will be required to provide Streamlined Energy and Carbon Reporting (SECR). The UK Financial Conduct Authority (FCA) requires companies with UK-listed shares to complete mandatory annual Task Force for Climate-Related Financial Disclosure (TCFD) aligned climate disclosure reporting.

Department for Energy Security and Net Zero requires UK-registered companies with over 500 employees or £500 million in annual revenue to complete annual sustainability and climate related disclosure reporting.

Hopefully this has given you food for thought on why managing energy and making efficiencies is essential to the continued success and profitability of your business. The next section talks about how a good energy management system works and the real benefits it brings to your business.

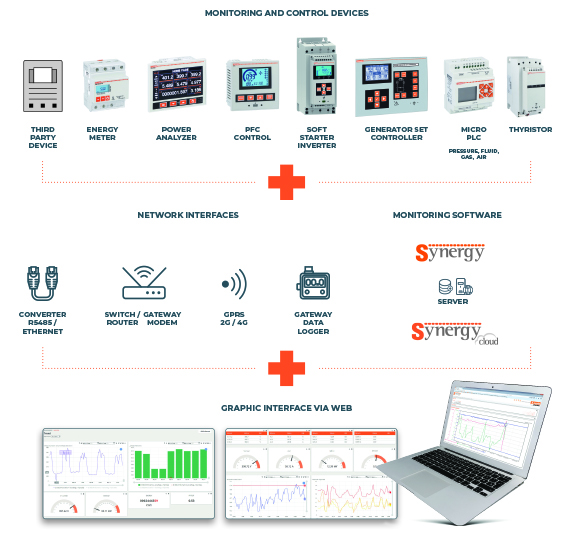

What is an energy management system?

An EMS in its simplest form is made up of four key ingredients:

- Monitoring and control hardware: fitted locally to each device

- Network interfaces: to translate and transmit from hardware to software

- Monitoring software: to store data securely and act as a gateway to the interface

- Graphic interface: web-based portal to provide user access to monitoring, control and reporting

What is an energy management system?

Energy meters

Devices that measure the amount of electrical energy consumed by a residence, business, or electrically powered device. They record usage over time to facilitate billing and energy management.

Power analysers

Instruments that measure various parameters of electrical power, such as voltage, current, power factor, frequency, and harmonics. They provide detailed insights into power quality and energy efficiency.

PFC (power factor correction controller)

A device used to improve the power factor of electrical systems. It manages the reactive power by adjusting the amount of inductive or capacitive load to minimise energy loss and improve efficiency. This results in reduced electricity costs and less strain on the electrical infrastructure.

Soft starter

A device used to gradually ramp up the power supplied to an electric motor, reducing mechanical stress and electrical surge. It helps in extending the lifespan of motors and decreasing maintenance costs.

Inverter

A device that converts DC (direct current) to AC (alternating current). Inverters are commonly used in solar power systems to convert the DC electricity generated by solar panels into AC electricity for use in homes and businesses.

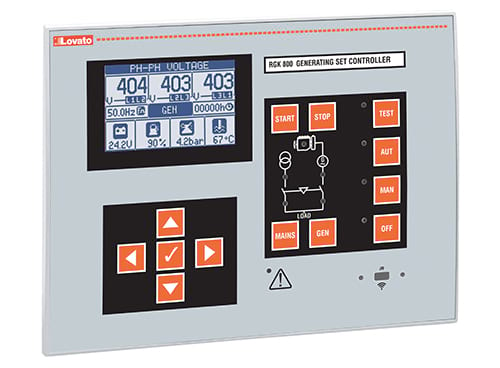

Genset (Generator set) controller

A device that manages and monitors the operation of a generator. It ensures efficient and safe operation by controlling start-up, shutdown, load sharing, and monitoring engine parameters and faults. It is crucial for reliable backup power supply.

Thyristor

A semiconductor device used to control and switch high voltage and high current in electrical circuits. It acts as a switch that can turn on and off the flow of electricity, commonly used in power electronics applications like motor speed controls, light dimmers, and pressure control systems.

Micro PLC (Programmable logic controller)

A compact and cost-effective version of a PLC, used for automation of industrial processes. It is designed for small-scale control applications, offering features like input/output control, timing, counting, and basic arithmetic operations. It is essential for automating machinery and improving operational efficiency in smaller setups.

Network interfaces

Converter RS485 & ethernet

A device that converts data between the RS485 serial communication standard and Ethernet, allowing integration of devices with RS485 interfaces into modern Ethernet networks. This enables remote monitoring and control of devices like energy meters and industrial equipment over IP networks

Converter RS485 & ethernet

A device that converts data between the RS485 serial communication standard and Ethernet, allowing integration of devices with RS485 interfaces into modern Ethernet networks. This enables remote monitoring and control of devices like energy meters and industrial equipment over IP networks

Router / Gateway modem

A networking device that forwards data packets between computer networks, creating an overlay network. In energy management systems, routers connect different network segments, manage traffic, and enable communication between devices and the internet, facilitating remote access and control.

GPRS

A mobile data service on 2G and 3G cellular communication systems. In energy management, GPRS enables wireless data transmission from remote or mobile energy devices to central monitoring systems. It facilitates real-time data transfer and remote management of distributed energy resources.

Monitoring software

On-site software

Monitoring software installed on a physical/virtual/cloud server owned and supplied by the customer.

SQL data storage

Secure storage device with connection to online web server.

Cloud-based

monitoring service

Graphic interface

A secure web-based application to monitor historical and live information on everything from a single component and machinery, through to whole departments and buildings. From the dashboard, you can also control and automate reporting, making decisions and planning a much simpler process.

What can an energy management system do for you?

Implementing an energy management system offers numerous benefits, including cost savings, improved efficiency, enhanced sustainability, increased reliability, data-driven decision-making, scalability, control, employee engagement, and financial incentives. These advantages make energy management systems a valuable investment for businesses looking to optimise energy use and achieve your sustainability goals.

COST SAVINGS REDUCED

ENERGY CONSUMPTION

By monitoring and optimising energy use, businesses can significantly reduce their energy consumption, leading to lower utility bills.

Peak Demand Management: Managing peak energy usage can avoid costly peak demand charges and potential penalties

IMPROVED EFFICIENCY

OPERATIONAL OPTIMISATION

Energy management systems help identify inefficiencies in processes and equipment, enabling improvements that enhance overall operational efficiency.

Automated Controls: Automated systems can adjust lighting, heating, cooling, and equipment usage based on real-time data, further optimising energy use.

ENHANCED SUSTAINABILITY REDUCED CARBON FOOTPRINT

Lower energy consumption translates to reduced greenhouse gas emissions, contributing to sustainability goals and environmental responsibility.

Compliance with Regulations: Helps ensure compliance with environmental regulations and standards, potentially avoiding fines and enhancing corporate reputation.

INCREASED RELIABILITY

PREDICTIVE MAINTENANCE

Continuous monitoring can predict when equipment is likely to fail, allowing for preventive maintenance that reduces downtime and extends equipment lifespan.

Improved Power Quality: Managing power quality issues such as voltage sags, surges, and harmonic distortion can improve the reliability of electrical systems and reduce the risk of equipment damage.

DATA-DRIVEN DECISION MAKING

Real-Time Monitoring Provides real-time insights into energy usage, allowing for immediate adjustments and better decision-making.

Historical Analysis: Analysing historical energy data helps identify trends and opportunities for further efficiency improvements.

SCALABILITY AND FLEXIBILITY

SCALABLE SOLUTIONS

Energy management systems can grow with your business, accommodating increasing energy demands and integrating new technologies as needed.

Flexibility: Systems can be customised to meet the specific needs of different industries and operational requirements.

ENHANCED CONTROL AND VISIBILITY CENTRALISED CONTROL

Offers a centralised platform to monitor and manage energy usage across multiple sites or facilities.

Visibility: Provides detailed visibility into energy usage patterns, helping to identify areas for improvement and track the impact of energy-saving measures.

EMPLOYEE ENGAGEMENT AWARENESS

Promotes awareness of energy use among employees, encouraging more energy-efficient behaviours.

Involvement: Engaging employees in energy-saving initiatives can foster a culture of sustainability within the organisation.

FINANCIAL INCENTIVES REBATES

AND INCENTIVES

Taking advantage of government and utility rebates and incentives for energy efficiency projects can further reduce costs.

Increased Property Value: Energy-efficient buildings and facilities can have higher market values and attract environmentally conscious tenants or buyers.

Find out more about how an energy management system could benefit your business

At LOVATO Electric, we offer cutting-edge products that oversee network monitoring, load management, and installation consumption.

Our approach centres on continuous data monitoring and in-depth analysis. By harnessing this information, we facilitate strategic planning to curtail energy usage. Moreover, our solutions ensure the availability of emergency power sources, guaranteeing uninterrupted operations when required.

Discover how our innovative solutions pave the way for efficient energy utilisation, enabling your business to thrive while minimising your ecological footprint.