Electromechanical Starters and Enclosures

The Heart of Industrial Operations

In the realm of industrial machinery, where precision and reliability are paramount, electromechanical starters and enclosures stand as the unsung heroes, orchestrating the smooth initiation and operation of complex systems. These components form the backbone of numerous industrial applications, ranging from manufacturing plants to transportation systems. In this blog, we delve into the intricacies of electromechanical starters and enclosures, unravelling their significance, functionality, and the myriad of benefits they offer.

Understanding Electromechanical Starters

At its core, an electromechanical starter serves as a device that controls the flow of electrical power to a motor, facilitating its efficient and controlled operation.

Unlike their purely electronic counterparts, electromechanical starters integrate both electrical and mechanical components to initiate and regulate the functioning of motors.

Components of Electromechanical Starters

Contactor

The primary element of an electromechanical starter, the contactor, consists of electromagnetically operated switches responsible for controlling the electrical current flow to the motor. When activated, the contactor connects or disconnects the power supply to the motor, enabling its start, stop, and protection.

Overload Relay

To prevent motor damage due to excessive current flow, electromechanical starters incorporate overload relays. These devices monitor the current passing through the motor and trip the circuit in case of overload conditions, safeguarding against overheating and potential damage.

Auxiliary Contactors

Supplementary to the primary switching function of the contactor, auxiliary contacts provide additional control capabilities, such as signalling for remote monitoring, interlocking with other systems, or initiating auxiliary functions.

Benefits of Electromechanical Starters

Reliability

Electromechanical starters boast robust construction and simple yet effective design principles, rendering them highly reliable in harsh industrial environments. Their mechanical components offer durability and resilience, ensuring consistent performance over extended periods.

Ease of Maintenance

Compared to electronic starters, electromechanical variants are often easier to maintain and troubleshoot. Their straightforward design facilitates swift identification and rectification of faults, minimizing downtime and enhancing operational efficiency.

Compatibility

Electromechanical starters exhibit compatibility with a wide range of motors, making them versatile solutions for diverse industrial applications. Whether driving small-scale machinery or powering

heavy-duty equipment, electromechanical starters can be tailored to suit specific requirements.

Cost-Effectiveness

Despite the advent of electronic starters, electromechanical counterparts remain cost-effective options for many industrial setups. Their simplicity in design and construction translates to lower initial investment and reduced long-term operational costs.

The importance of enclosures: Ensuring Safety and Protection

In conjunction with electromechanical starters, enclosures play a pivotal role in ensuring the safety and integrity of industrial electrical systems.

These protective housings shield the components from environmental factors, mechanical damage, and unauthorized access, thereby prolonging their lifespan and enhancing operational safety.

Types of Enclosures

IP Enclosures

Utilised primarily in European markets, IP (Ingress Protection) enclosures follow a similar principle of categorisation based on their resistance to dust and moisture ingress. The IP rating system classifies enclosures according to their degree of protection, offering clarity regarding their suitability for different environments.

NEMA Enclosures

Defined by the National Electrical Manufacturers Association (NEMA), who set standards for North America, these enclosures adhere to standardised specifications, delineating their suitability for specific environmental conditions. Ranging from NEMA 1 for indoor use to NEMA 4X for harsh outdoor environments, these enclosures cater to diverse application requirements.

In the intricate tapestry of industrial operations, electromechanical starters and enclosures emerge as indispensable components, orchestrating the seamless initiation and regulation of machinery. Their robustness, reliability, and compatibility make them stalwarts in diverse industrial settings, ensuring the smooth and efficient functioning of critical systems. As industries evolve and embrace technological advancements, electromechanical starters and enclosures continue to stand firm as pillars of stability, driving progress and innovation in the ever-expanding landscape of industrial automation.

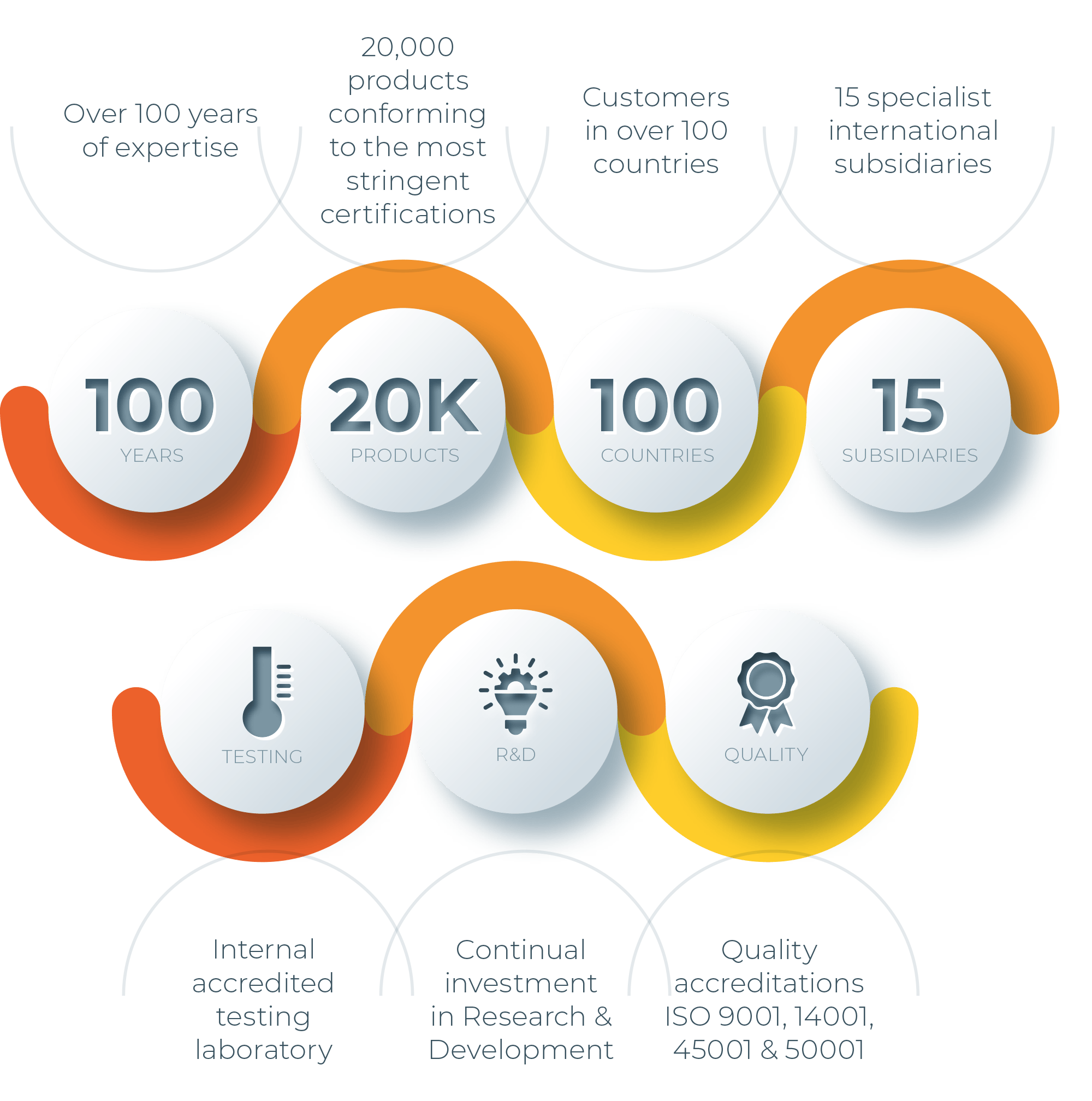

Why choose Lovato?

Make the Switch to Lovato Electric Today!

Elevate your industrial operations with the unmatched reliability, innovation, and support of Lovato Electric. Join the ranks of satisfied customers worldwide who have chosen Lovato Electric as their preferred supplier of electromechanical starters and enclosures. Experience the difference firsthand and take your business to new heights of success.

Contact us now to learn more about our comprehensive range of electromechanical solutions and discover why Lovato Electric is the preferred choice for discerning industrial professionals.

Follow us on LinkedIn for the latest innovations.