In industrial settings, electric motors are the largest consumers of energy. While efficient motors and inverters help reduce consumption, businesses must actively monitor and quantify energy usage to optimise performance and cut unnecessary costs.

Quick fixes to reduce energy waste

One of the simplest yet most overlooked ways to reduce wasted energy is ensuring that equipment only runs when needed. Common culprits of continuous energy waste include:

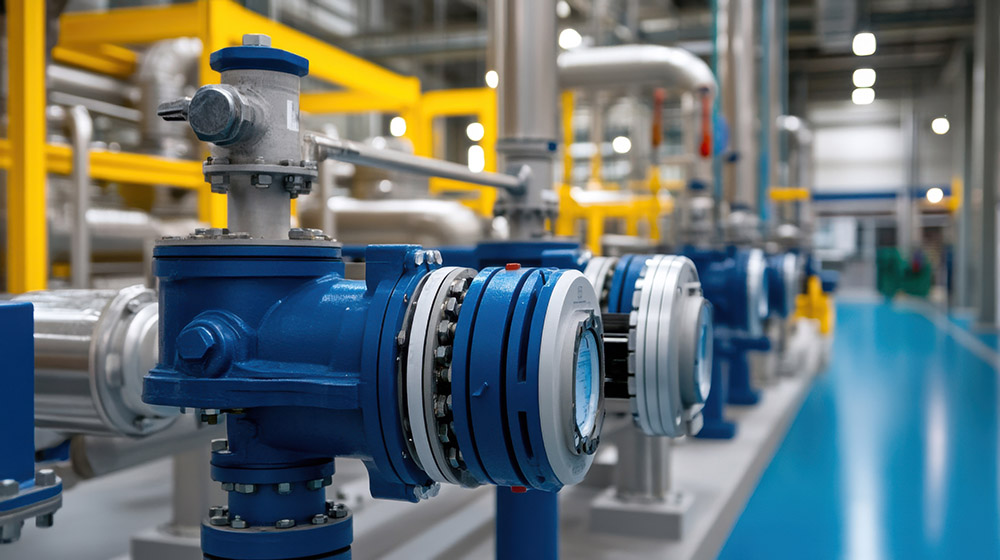

Fans, compressors, and pumps left running unnecessarily

Fans, compressors, and pumps left running unnecessarily

Reduce reactive power to optimise efficiency

Electric motors require two types of power:

- Active Power (kW) – The power used to produce motion.

- Reactive Power (kVAr) – The power needed to energise the motor’s magnetic field.

The total power a motor draws is known as Apparent Power (kVA), which combines both Active and Reactive Power. Without correction, businesses pay for full Apparent Power while only actively using a portion of it.

How to correct reactive power

To minimise unnecessary energy consumption and costs, capacitors can be installed locally to balance Reactive Power. This reduces the load on the electrical network and prevents excess power from flowing back to the utility provider, leading to significant savings. An effective monitoring system can pinpoint where preventive solutions are needed, ensuring motors operate at peak efficiency.

The role of Energy Management Systems (EMS)

An Energy Management System (EMS) is a powerful tool that enables businesses to track, control, and optimise their energy consumption.

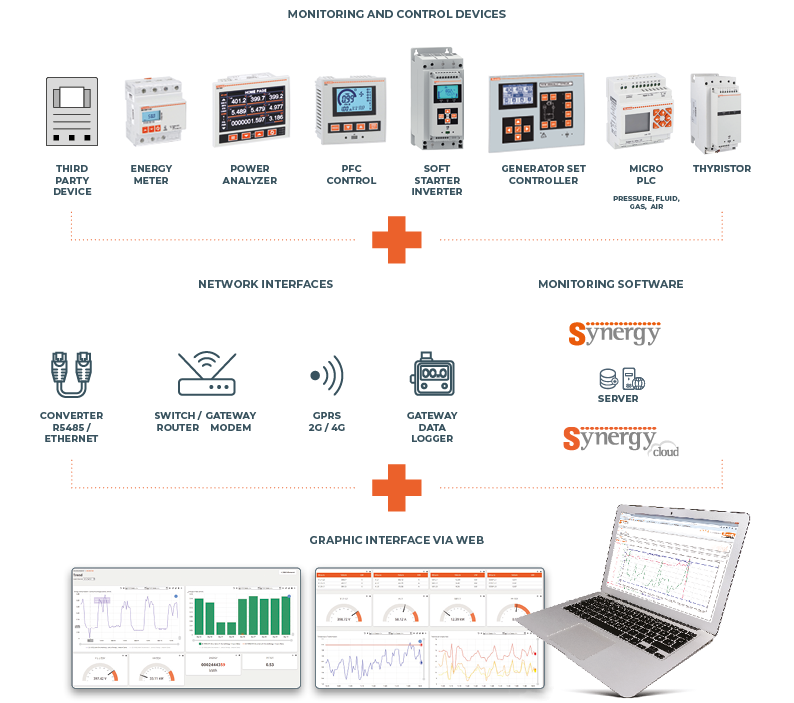

A typical EMS consists of:

- MONITORING AND CONTROL HARDWARE – Devices installed on equipment to measure energy usage.

- NETWORK INTERFACES – Facilitating data transmission between hardware and software.

- MONITORING SOFTWARE – Securely storing and analysing data.

- GRAPHIC INTERFACE – A user-friendly web portal for monitoring and reporting.

Benefits of implementing an EMS

COST SAVINGS

Reduced energy consumption leads to lower operational costs

COST SAVINGS

Reduced energy consumption leads to lower operational costs

IMPROVED EFFICIENCY

Optimised equipment performance ensures minimal waste

ENHANCED SUSTAINABILITY

INCREASED RELIABILITY

Predictive maintenance prevents unexpected downtime

REAL-TIME MONITORING

SCALABILITY & FLEXIBILITY

Adaptable solutions grow with business needs

EMPLOYEE ENGAGEMENT & AWARNESS

Encourages energy-conscious workplace habits

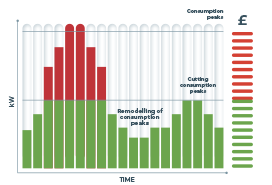

Hidden costs: The energy consumption peak

Did you know that exceeding your energy consumption limit can result in penalties and push your business into a higher tariff? This can drastically increase production costs and erode profitability without realising it.

How LOVATO Electric can help

At LOVATO Electric, we provide state-of-the-art solutions for network monitoring, load management, and energy optimisation. Our approach is centred on continuous data monitoring and in-depth analysis, enabling businesses to strategically reduce energy waste while ensuring uninterrupted operations.

Take control of your energy costs

By implementing an energy management system, businesses can achieve substantial cost savings, improved efficiency, and greater control over their energy usage.

Find out more in our free comprehensive guide on energy management