Powering Trust, Safeguarding Motors

Lovato Learning Hub: Motor Protection Circuit Breakers.

What are Motor Protection Circuit Breakers?

Motor Protection Circuit Breakers (MPCBs) are essential components in safeguarding electric motors from electrical faults and overload conditions. MPCBs serve as a crucial line of defence for electric motors, designed to provide reliable protection for motors by interrupting the power supply in case of abnormalities in the electrical circuit. They combine the functionalities of both circuit breakers and overload relays in a single unit. These devices are installed in series with the motor and constantly monitor the current flow through the motor circuit.

Their ability to detect overloads, short circuits, and phase imbalances makes them indispensable components in industrial and commercial settings. With various types available, users can select MPCBs that best suit their specific motor protection needs, promoting safety and reliability in electrical systems.

Let’s dive deeper into understanding what MPCBs are, their benefits, and the various types available in the market.

Key benefits of Motor Protection Circuit Breakers.

Overload Protection

MPCBs prevent motors from overheating and burning out due to excessive current flow, ensuring their longevity and efficiency.

Short Circuit Protection

They swiftly interrupt the power supply in case of short circuits, preventing damage to the motor and the electrical system.

Phase Failure Protection

MPCBs detect phase imbalances and protect motors from damage caused by phase failure.

Remote Control and Monitoring

Some advanced MPCBs offer remote monitoring and control features, enabling efficient management of motor operations.

Compact and Efficient

They come in compact sizes, saving space in electrical panels while providing robust protection to motors.

What are the different types of Motor Protection Circuit Breakers?

Thermal /magnetic Overload

These operate based on the motor’s current draw, using a bimetallic strip to trip the circuit when the current exceeds a specified level for a set duration.

Magnetic Trip

They use an electromagnetic coil to detect sudden spikes in current and trip the circuit to protect the motor.

Manual Reset

After a trip due to overload or fault, these require manual intervention to reset the breaker, ensuring safety measures are acknowledged before restarting the motor.

Adjustable Trip

These allow users to adjust trip settings based on the motor’s specific requirements, providing flexibility in protection.

What are the typical applications for MPCBs?

Motor Protection Circuit Breakers (MPCBs) are commonly used in various machines and equipment that rely on electric motors for their operation. Some of the machines that typically utilize MPCBs for motor protection include:

Industrial Machinery

Equipment in manufacturing plants such as conveyor belts, pumps, compressors, fans, mixers, and other heavy machinery often incorporate electric motors and rely on MPCBs for motor protection.

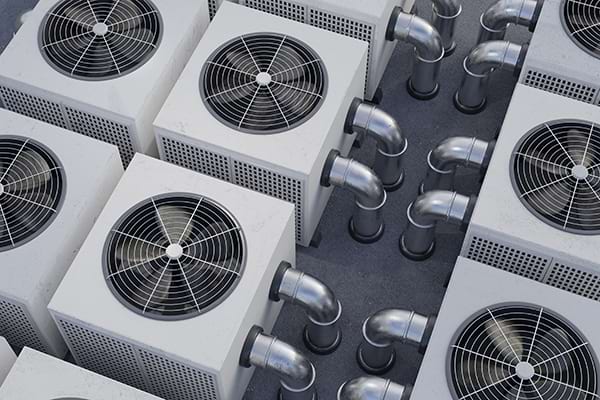

HVAC Systems

Heating, ventilation, and air conditioning systems utilize motors for fans, blowers, and pumps. MPCBs ensure the protection of these motors against faults and overloads

Elevators and Escalators

Electric motors power the movement of elevators and escalators. MPCBs are crucial in these systems to prevent motor damage due to various electrical faults.

Water Treatment Systems

Motors in water pumps and filtration systems, used in both industrial and residential settings, are safeguarded by MPCBs to ensure uninterrupted operation.

Machine Tools

Equipment like lathes, drills, milling machines, and saws that rely on electric motors utilize MPCBs for motor protection against electrical faults.

Conveyors and Material Handling Equipment

Motors powering conveyor systems and material handling equipment in warehouses, distribution centres, and manufacturing facilities are protected by MPCBs

Commercial Appliances

Some larger commercial appliances like dishwashers, washing machines, and dryers may incorporate electric motors and benefit from the protection provided by MPCBs

Pumping Stations

In facilities requiring the movement of fluids or gases, pumps often rely on electric motors. MPCBs are integral in safeguarding these motors against electrical faults.

Mining Equipment

Heavy machinery used in mining operations, including drills, haul trucks, and excavators, often rely on electric motors that are protected by MPCBs.

UL ratings Type E and Type F combination motor controllers

The UL standard indicates a combination motor controller, also called a combination starter, as equipment consisting of a protected starter incorporating an isolation function. The protection includes both thermal overload and short circuit. In the standard of UL508 (now harmonized with IEC as UL 60947-4-1), we can find different construction types of starters stated as Type A, Type B, etc… composed of different type of devices intended to control, disconnect, and protect a motor. Type E and Type F controllers usually provide the best solution to control and protect a motor.

Lovato’s Motor Protection ranges

The Lovato range offers a wide adjustment range of 0.1 to 100A with an IEC breaking capacity Icu up to 50kA (400V). All MPCBs are suitable for isolation certification UL Type E and Type F and have high reliability and accuracy of tripping.

LOVATO Electric motor protection circuit breakers are suitable for new motors with high IE3 efficiency values and are tested to endure 100,000 cycles in their mechanical and electrical lifetime. All of the devices, in both the rotary knob type and push button-controlled motor protection circuit breaker range, can be padlocked, this provides greater operator safety during maintenance and bypassing of equipment.

The key benefits

Compliance

IEC/DIN/EN/BS/UL

Easy installation

SM1P can be mounted in

any modular enclosure

Reliable

Tested to 100,000 cycles

Certificated

cULus/EAC

Security

Can be padlocked in the off position

SM1P and SM1R ranges are modern circuit breakers with thermal and magnetic trip releases and high breaking capacity.

Lovato’s range of MPCBs provide complete motor control and protection up to 22kW (400V) by choosing the suitable adjustment range, 0.1 to 40A.

MPCB Frequently Asked Questions

Is it possible to use the motor protection circuit breakers to protect single-phase motors?

Yes, but a simple trick in the wiring must be implemented, that is, have the current pass through the three phases of the motor protection switch. In practice, a phase must pass through two poles of the switches connected in series between them. Otherwise, the motor protection switch will trip off due to thermal intervention. The motor protection switches are in fact sensitive to phase failure. Note that the same practice must also be implemented with thermal relays.

What are the main constructive and functional differences between the SM1P and SM1R series motor protection circuit breakers?

The main constructive difference is the actuator which is push-button for the SM1P type and rotary knob for SM1R. The SM1P type has smaller dimensions so it can be mounted in modular panels. SM1R has a higher breaking capacity and is equipped with a trip position in which it is possible to distinguish whether the trip occurred for thermal overload or short circuit.

Is it possible to connect a motor circuit protection circuit breaker downstream of a variable speed drive (inverter)?

Yes, it is possible. However, it must be considered that there is a greater heating of the thermal protection (resistors and bimetals) as a result of the eddy currents generated by harmonics and the skin effect of high frequencies. It may therefore be necessary to set the adjust to a current slightly higher than the current absorbed by the motor to avoid unwanted thermal tripping. On average of +20%. In practice, if we have a motor that absorbs 10A, the thermal adjuster of the motor protection circuit breaker must be set to 12A. [More FAQs]

Ask Lovato about the right solution for your application.

Call 01384 899700 or use our contact form and speak to one of our advisors. Follow us on LinkedIn for the latest from Lovato UK.